Dip soldering is a small-scale soldering process by which electronic components are soldered to a printed circuit board (PCB) to form an

electronic assembly. The solder wets to the exposed metallic areas of the board (those not protected with solder mask), creating a reliable

mechanical and electrical connection.

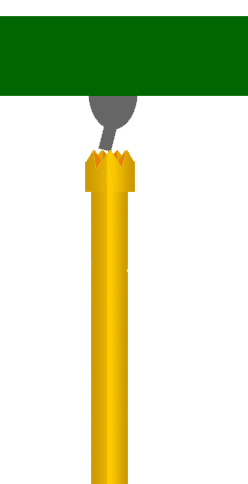

Generally, the test crown is chosen to touch the dip on the board. When we are concerned with

the flux on the dips, we usually use five-blade head (HAA) and tulip head (T).

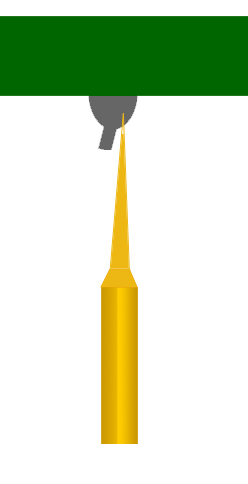

Also,we have another great solution for Dip test,R(sharp steel head) is good choice.R is so aggressive,tip

could touch in pad, not test the dip,and also the board is enough thick.